TURNING OFF / ISOLATING YOUR WATER COOLERS OR HOT DRINKS BOILER IN CASE OF A LEAK – OR IF LEAVING YOUR SITE UNATTENDED

If you have concerns that your plumbed in water cooler / mains water dispenser / hot drinks water boiler are leaking, then it is imperative that they are isolated immediately. Leaks that seem small during the day, can get worse at night time, when pressure rises in the mains water. This meaning a small leak can become far worse when the site is shut – causing significantly more damage. If you have any concerns that there is a leak you must follow this guide immediately and prior to leaving your site overnight or for the weekend.

Before shutting off your water, it is also useful to establish the following:

Can you see where the leak is coming from? (tap / drip tray / back of machine / filter). Sometimes sites report leaks when it is actually poor maintenance of the cooler that is causing something that looks like a leak.

1. Please check that all drip trays have been fully emptied and are not overflowing

2. Please ensure that no one has spilt a drink on the floor and not cleaned it up

3. If you have a water cooler with an internal waste collection kit – please ensure that this has been emptied. These are found in the base of your Floorstanding cooler and are connected to the drip tray. They are large plastic containers that collect drip tray overflow, and if not emptied, water will leak into the base cabinet – giving the impression of a leak.

Please then undertake the following action:

1. Isolate the mains supply

The majority of mains water coolers / plumbed in water coolers / plumbed water dispensers/mains water dispensers / hot drinks boilers are fitted with either ¼ inch or 3/8 white or blue flexible tubing. If further than a few feet away from the mains connection point an isolating valve can be found connected to the tubing at the back of the mains water cooler/mains water boiler.

Turn this isolating valve clockwise by ¼ – this will isolate water to the machine.

This is ON

This is OFF

2. Turn off the cooler / hot drinks boiler at the electrical socket.

Once you have isolated your cooler / hot drinks boiler please ensure it is turned off at the electrical socket. For hot drinks boilers, this means that they will no longer heat up – making it easier for you to drain them. If your machine has solenoid valves – this will also ensure they cannot leak.

Turn Off via the lever

3. Drain your machine.

Please then drain your cooler / boiler. To do this simply place a jug under all taps and dispense. If you have isolated your machine as per above the flow should start to slow down and then stop. Please bear in mind that coolers can have up to 3 litre of water in them and a boiler might have up to 10 litres of water inside, so this make take a few minutes to achieve. This is important as if the leak is coming from inside the reservoir – then there is anywhere between 3-10 litres of water that can still leak out if you miss this vital step.

You should now see the leak lessen and stop.

4. Isolate the mains supply via the connection point

Check its not your pipework that’s leaking.

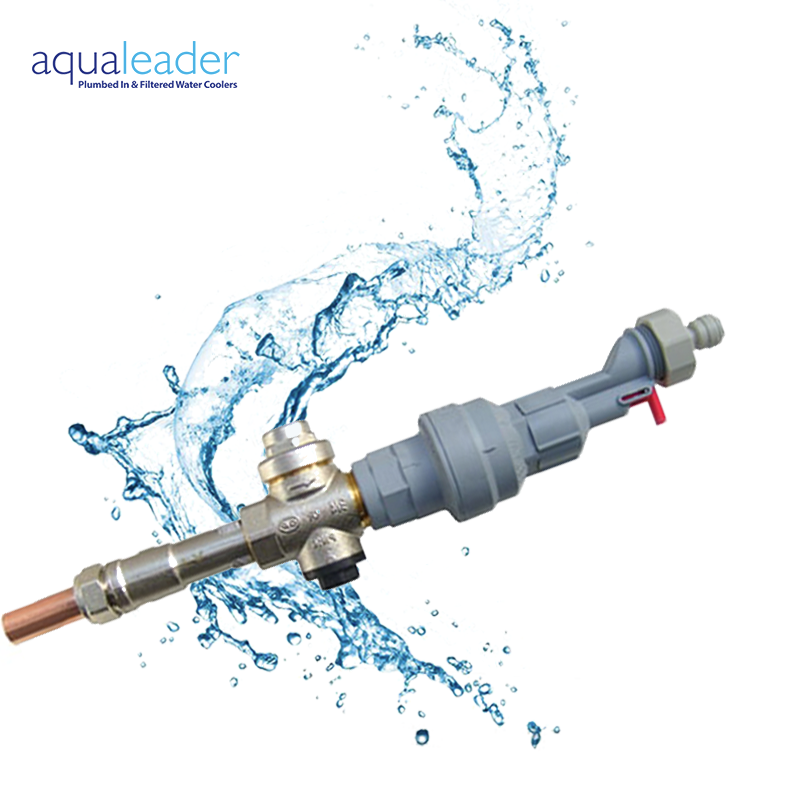

If the machine is not the cause of the leak and you think the leak is coming from the mains water connection, then you will need to isolate the whole section of pipe, at source. We would also suggest that you isolate at the point of connection for all suspected leaks – just to be doubly sure that no further water ingress can occur. In most cases, the mains connection point is usually underneath a sink and the isolator will look like the below image:

Turn Off via the lever / washing machine valve part – a further view of this part is below:

Washing Machine Valve in Open Position

The part above is typically called a washing machine valve. Please ensure the part is in the OFF position and drain the machine and turn off the electrics – as per steps 2 and 3 .

For further assistance please email: help@aqualeader.co.uk where our team are ready to assist.

Equally if you are a school or a factory that intends to shut your site for longer than a standard weekend, we recommend following steps 1 / 2 and 3 to ensure no leaks occur when your site is not attended.